It is a source of joy for us that you have revealed rate of interest in this post on Voluum Medicine.

The $79 Starter strategy is suitable for new marketing experts and provides a fundamental set of monitoring functions. The Standard and Pro plans offer innovative attributes and more capability.

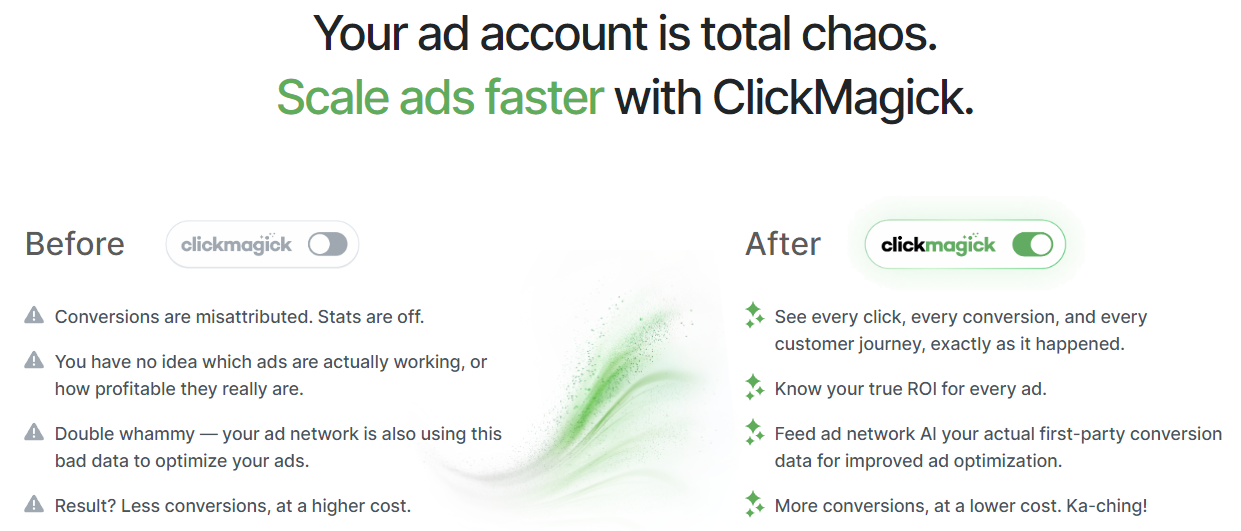

These features include click fraud tracking and website traffic high quality analysis. They also offer a harmonious dashboard of marketing metrics. These tools can revolutionize your advertisement optimization video game.

Straightforward interface

Clickmagick is a powerful tool that enables you to track and optimize all conversion objectives. Its easy to use user interface makes it easy to use for beginners. This makes it a great option for affiliate marketers and anybody that acquires or sells traffic. It likewise has functions that assist you track ROI and even more.

Its innovative acknowledgment models give quality and self-confidence, enabling you to make data-driven decisions that improve efficiency and maximize ROI. It additionally helps you improve ads and budgets making use of real-time data, conserving money and time. Unlike various other marketing devices, Voluum Medicine eliminates short acknowledgment home windows, greedy attribution and estimates by immediately looking through clicks to strain crawlers and spam.

Its Scarcity Tool is a proven conversion-boosting method that produces a feeling of seriousness to urge site visitors to act. This is essential due to the fact that lots of people don’t have the moment to spend hours looking into a product and services. It additionally provides individuals with a clear photo of their project’s effectiveness by showing them where they base on the conversion chart. It also provides an adjustable UI that makes it easy to use also for newbie affiliates.

Easy to install

ClickMagick is a simple click monitoring and optimization option that can supercharge your advertising and marketing initiatives. Its advanced acknowledgment versions help you comprehend the full client journey and optimize your roi. The system also provides a central control panel that provides all of your vital metrics in one place.

Its simplicity of setup is another function that makes it stand apart from competitors. You can conveniently incorporate it with your web pages and other third-party software program, including WordPress. Its pixel support enables you to develop pixels in HTML or JavaScript and it can even send out site visitors to various landing pages based upon their place or gadget type.

It likewise has the capacity to divide test links, allowing you to identify which version of your touchdown web page converts ideal. The tool will automatically monitor each web link, changing its web traffic allotment to discover the champion. Additionally, it tracks offline conversions, allowing you to see how your advertisements are executing in real life. You can get individually support from the group if you need assistance and it updates you routinely about system standing.

Assimilation with significant advertisement networks

ClickMagick has the capacity to incorporate with significant ad networks, including Facebook and Google. This feature serves for online marketers that run ads across numerous platforms, as it helps them determine their ROI and concentrates on one of the most rewarding projects. It additionally supplies tools to optimize their campaigns continuously. This consists of detecting spam and robot clicks, and automating split testing to discover which landing page offers the best opt-in percent.

An additional crucial feature is the conversions by time report, which shows you when your sales and opt-ins typically surge. This data can help you align your ad spend with real-world patterns. This tool can save you money by preventing you from throwing away advertisement budget plan on unlucrative campaigns.

ClickMagick offers 3 plans: Starter, Standard and Pro. The Starter strategy is made for new customers and includes fundamental monitoring features. The Standard plan uses more advanced features, such as PPC click guard, cross-device tracking and recurring profits tracking. It additionally consists of more than 100,000 clicks each month, 5 channel tracking and a personalized tracking domain name.

TrueTracking

A crucial feature that sets ClickMagick besides other trackers is its capability to send out conversion data back to advertisement networks. This allows you to make even more informed decisions and maximize your projects with precision. For example, you can discover hidden performance treasures in certain nations and identify peak engagement times. This is specifically valuable for avoiding over-spending on low-performing ads.

One more standout feature is Dynamic Sub-IDs, which offers you the power to add multiple identifiers to a single tracking web link. This is similar to classifying various instruments in a band, enabling you to analyze the resource of website traffic and conversions. It additionally enables you to leverage scarcity to urge your site visitors to do something about it and lower desertion prices.

Unlike complimentary options that supply basic insights, Voluum Medicine offers a scenic sight of your advertising landscape. It is more than a tool; it’s like the skilled captain on your team, steering you through the ins and outs of the digital sea. Additionally, its system condition attribute keeps you upgraded about advertisement network interruptions and various other possible missteps that can impact your project.

Final thought: Voluum Medicine

ClickMagick is a great device for any person that makes use of paid advertising to drive traffic to their websites. It can help them track clicks from distinct site visitors to make sure that they know who is truly converting. ClickMagick likewise helps them enhance their projects and maximize ROI. It enables them to strain bot clicks and other deceitful activity that could skew the outcomes of their information evaluation.

This software application can likewise track the efficiency of whole sales funnels, consisting of a site visitor’s trip from one page to the next. It can also instantly create split examinations with various variations of a URL to see which execute much better in terms of opt-in percent. This is very valuable in an advertising and marketing setting where conversions are usually highly depending on the individual’s behavior.

ClickMagick has 3 prices strategies that are developed to fit the demands of various marketing professionals. The Starter Plan is perfect for new marketing experts aiming to begin with precise monitoring and acknowledgment, while the Standard plan offers sophisticated attributes to maximize and scale campaigns. The Pro plan is focused on high-volume individuals and companies. It includes everything in the various other two plans plus a few added functions.